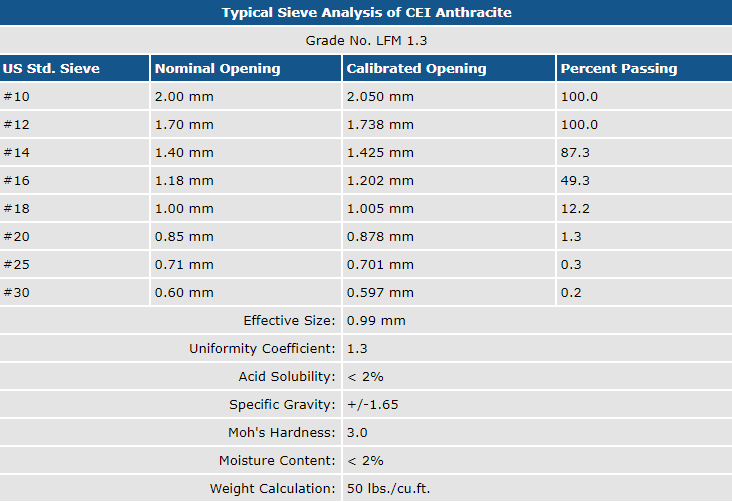

CEI Anthracite manufactures high quality, dry and low uniformity coefficient anthracite filter media.

CEI Anthracite’s <1.3 uniformity coefficient can provide many benefits in granular bed filters, including:

- Increased plant capacity by the use of higher filtration rates

- Lower backwash rates in dual- and tri-media filters

- Better production efficiency due to longer filter cycles at higher filtration rates

- State-of-the-art sizing plant to guarantee your specifications… ensuring complete production control and accurate processing.

- Automated sieve analyzer… assures consistent product quality permitting precise control of both the raw material and finished product.

- Automated high-speed bagging equipment… offering optional packaging in either one (1) cubic foot bags (or) one ton high-strength woven polypropylene fabric bags for fast and easy handling.

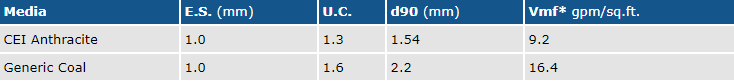

CEI Anthracite offers a customized comparative analysis between the uniformity coefficient of <1.3 and the traditional higher uniformity coefficients. The analysis summarizes the annual savings realized from reduced fresh water use.